Fiber laser welding machine 1000w 1500w 2000w 3000w weld metal thickness:

1, 1000W:0.5mm-2mm

2, 1500W: 0.5mm-3.5mm

3, 2000W:0.5mm-6mm

4.3000W : 6mm+

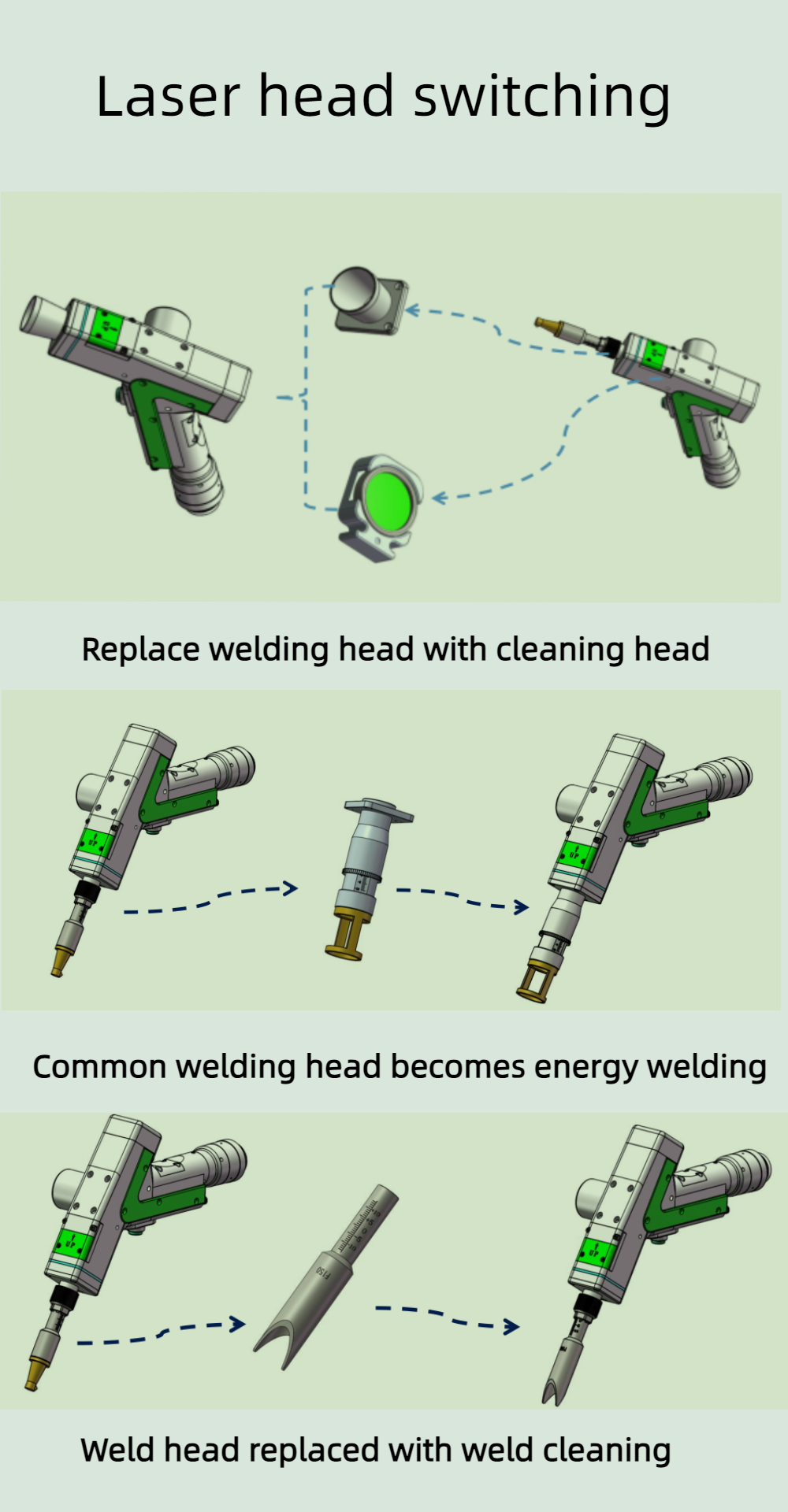

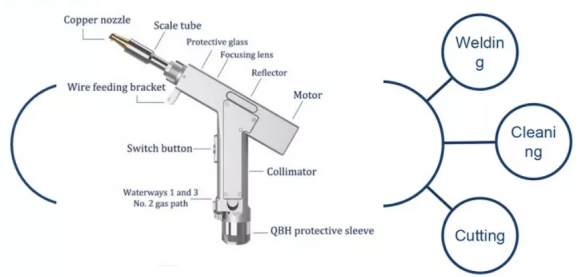

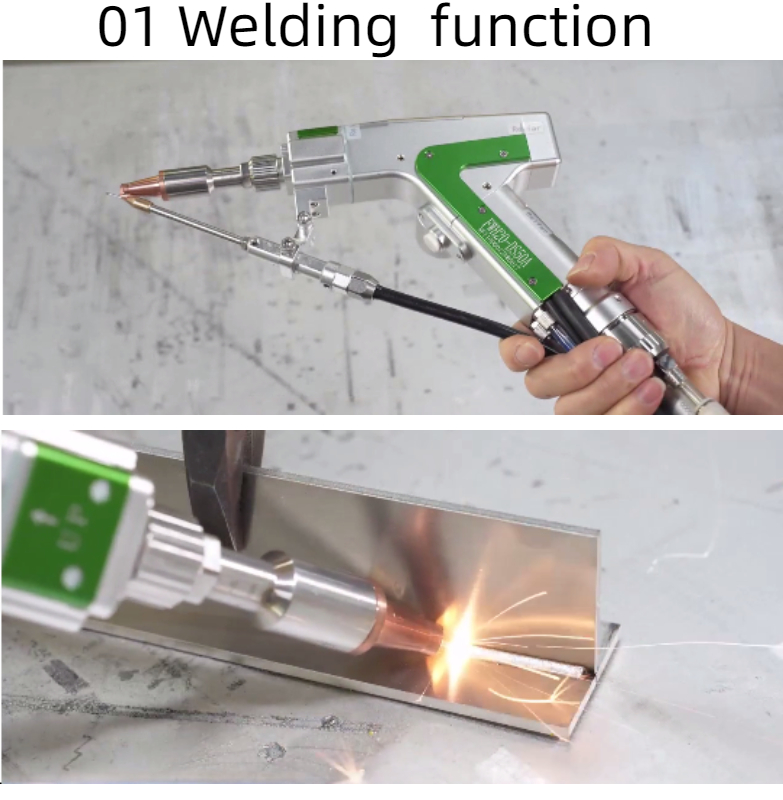

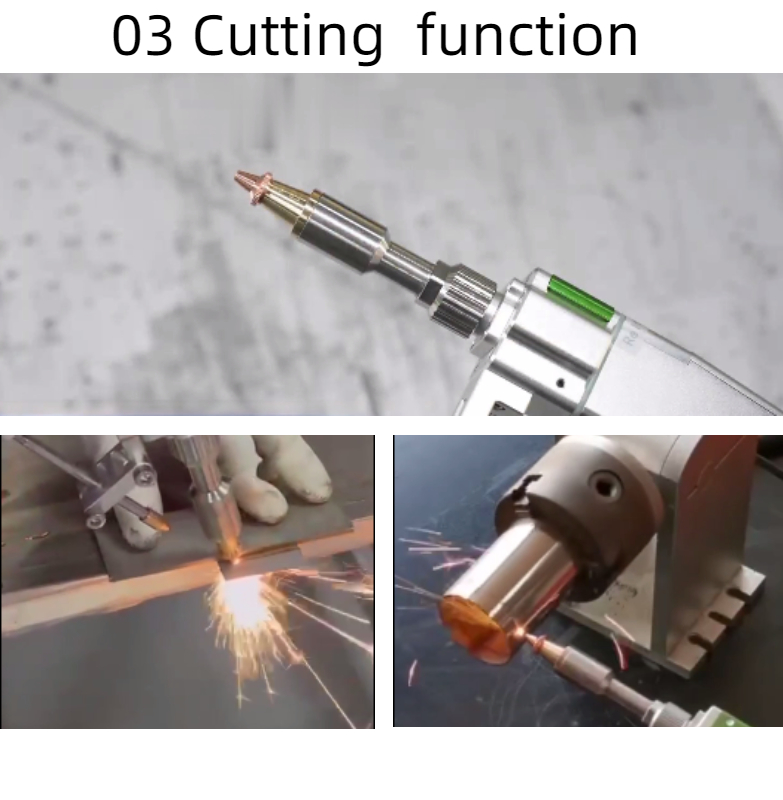

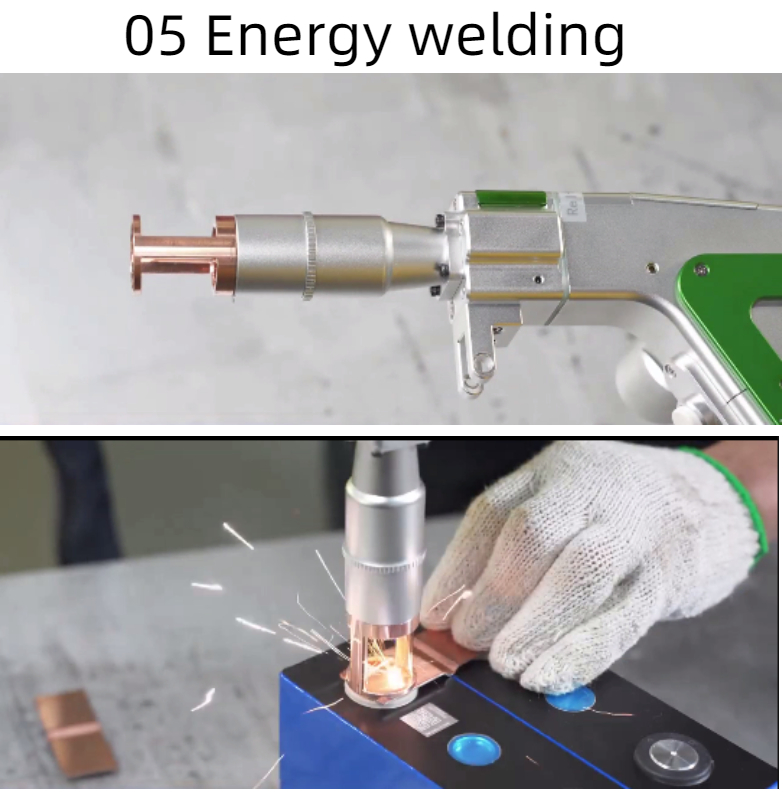

This machine adopts fiber laser to make welding/cutting/cleaning /energy welding with five-in-one welding head.

5 in 1 welding head integrates the five functions in one system. The system can make switch freely according to different application scenarios, providing diversified solutions for users' different application requirements.

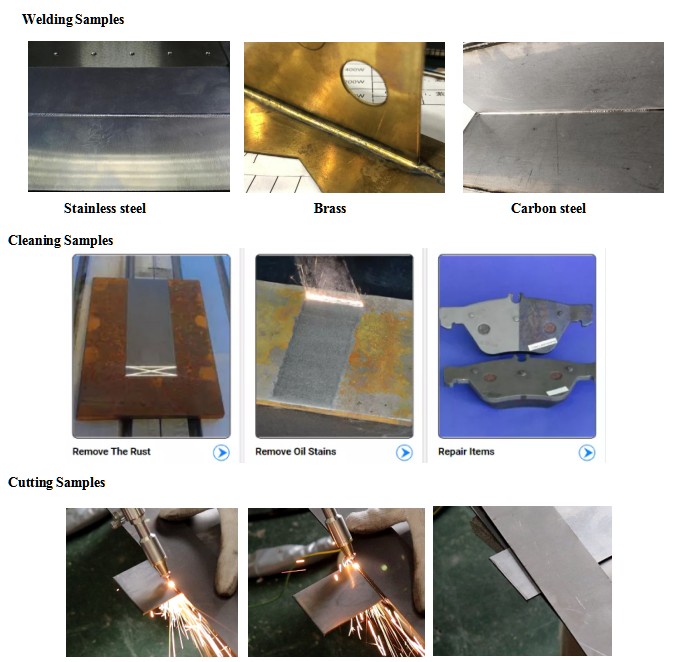

It's suitable for a welding base, cleaning required and simple cutting.

This multi-functions Laser machine mainly used for plastic mold of S136, SKD-11, NAK80, 8407, 718, 738, H13, P20, W302, 2344 mold steel, carbon steel, common alloy steel, stainless steel, beryllium copper, copper and extremely hard alloy material, Casting mold, forging die, stamping die, die casting molds.

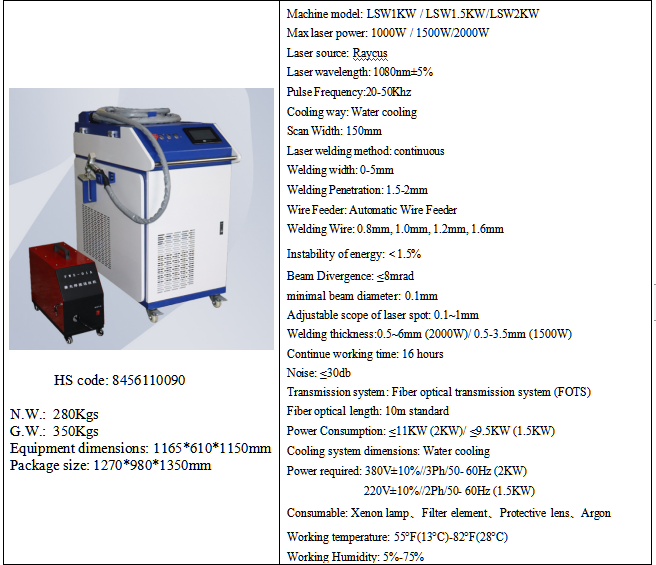

Machine model | LS1LW |

Max laser power | 1070 watt |

Laser source | Raycus |

Laser wavelength | 1064nm |

Pulse width | 0.1-25ms |

Laser welding method | continuous |

Instability of energy | <2% |

Beam Divergence | ≤8mrad |

minimal beam diameter | 0.1mm |

Adjustable scope of laser spot | 0.1~1mm |

Welding depth | 3~4mm |

Continue working time | 16hours |

Noise | ≤30db |

Transmission system | Fiber optical transmission system (FOTS) |

Fiber optical length | 10m standard |

Power Consumption | ≤7.2KW |

Cooling system dimensions | Water cooling |

Power required | 220V±10%/50Hz |

Consumable | Xenon lamp、Filter element、Protective lens、Argon |

Working temperature | 55°F(13°C)-82°F(28°C) |

Working Humidity | 5%-75% |

Oil mist | ≤15mg/m³ |

More details of the machine:

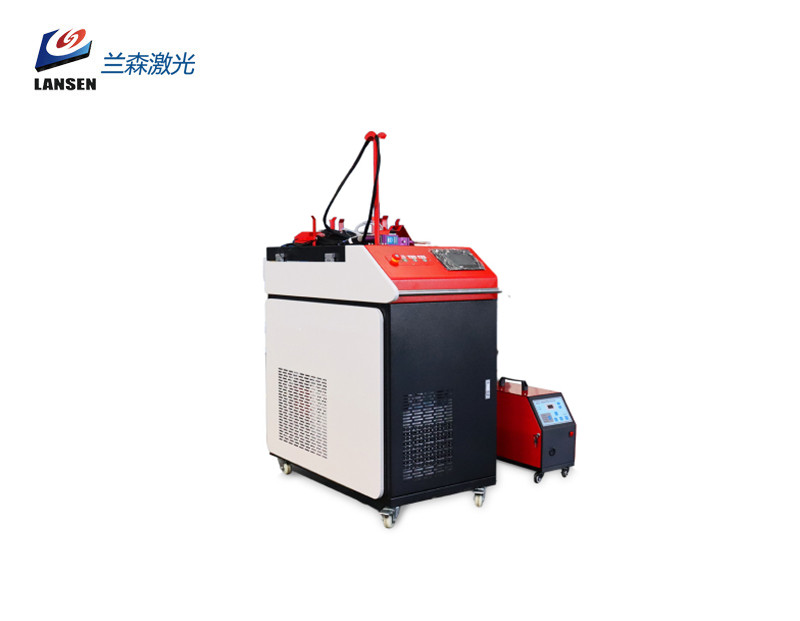

| Dual-drive Handheld Swing Laser Head There are 6 welding modes and multiple welding nozzles to meet different welding needs; it has a safety sensor function, which emits a laser after touching the metal and automatically locks the light when it is removed; the spiral jittery function, the width of the weld can be adjusted, and the welding ability is significantly improved.

| ||

A Variety Of Welding Modes It can be used in 6 models: -Point shape -one shape -0 shape -double 0 shape -triangle-figure eight welding It can deal with various welding scenes, to meet various welding requirements of customers | | ||

| Standard 10 Meters Optical Fiber It is conventionally equipped with 15-meter optical fiber, which can realize long-distance, flexible welding in large areas and reduce operating limitations

| ||

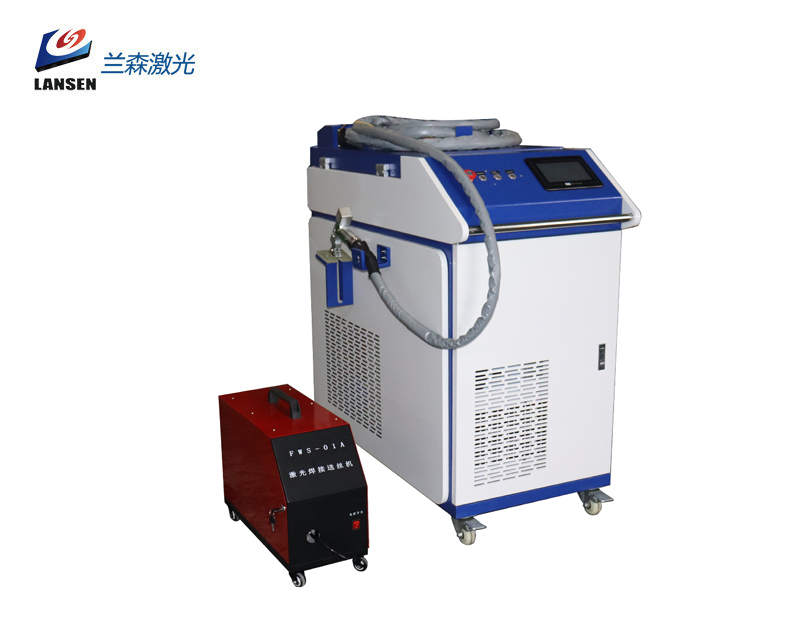

Auto Wire-feeder device The machine is equipped with automatic wire-feeder device, which can easily adjust the parameters and provide multiple choices for customers.It can effectively make up for the welding seam produced in the welding process, so that the welding more closely bonded.

|

| ||

Welding modes |

| ||

Work samples:

Parameters:

lansenlaser@hotmail.com

lansenlaser@hotmail.com +86 156 6577 8610

+86 156 6577 8610 lansenlaser

lansenlaser sales@lansenlaser.com

sales@lansenlaser.com