Application Industry

Our products are widely used in appliances, automobile parts, instrumentation, precision machinery, hardware tools, clothing accessories, gifts and so on. With the rich experience in designing and production, our products are sold worldwide. Due to the stable quality and low maintenance, our products are strongly favored by our valued customers.

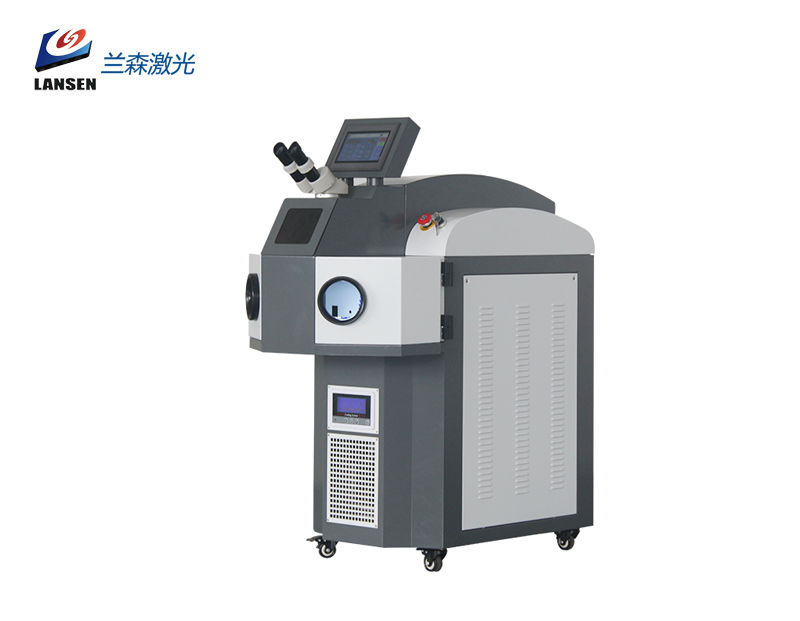

Introduction of Jewelry laser welding machine:

This welder is mainly used in perforating and spot welding of gold and silver jewelry. The laser spot welding is an important aspect of laser process technology application. The spot welding process is thermal conduction, i.e. the laser radiation heats the surface of work piece, and the surface heat diffuses to the interior through thermal conduction and melts the work piece by controlling the width, energy, peak power and repeating frequency of laser pulse to form specific molten pool. Because of its unique advantage, it is widely used in the process of gold and silver jewelry and welding of mini and small parts.

Application of jewelry laser welding machine:

Commonly used in gold and silver jewelry, golf heads, fill holes, Chlamydia trachomatis in spot welding, welding of electronic components inlaid ornament, stainless steel, titanium alloys, welding, repair of precision casting products, widely used in jewelry, electronics, watches, and other industries

Item Name | Parameter |

Model | IT-W200 |

Laser type | Nd:YAG |

Laser Wavelength | 1064nm |

Laser Power | 200W |

Laser Energy | 70J - 80J |

Pulse Width | ≤ 20ms |

Pulse Frequency | ≤ 50Hz |

Beam Diameter | 0.6-3.0mm |

Chamber Illumination | LED lamps |

Parameters Memorization | 10 groups |

Protection Alert | flow alert |

Language Display | Chinese/English (can be customized) |

Shield Gas Supply | One line |

Cooling System | Water cooling |

Power Consumption | ≤6KW |

Power Supply | 220V±10% /50Hz-60Hz |

Welding Chamber Dimensions | 300mm*450mm*150mm(L*W*H) |

Machine Dimensions | 1000mm*570mm*1200mm (L*W*H) |

Running Environment | 5℃-30℃, 5%-75% humidity |

Net Weight | 155kg |

Work samples:

2. Machine details

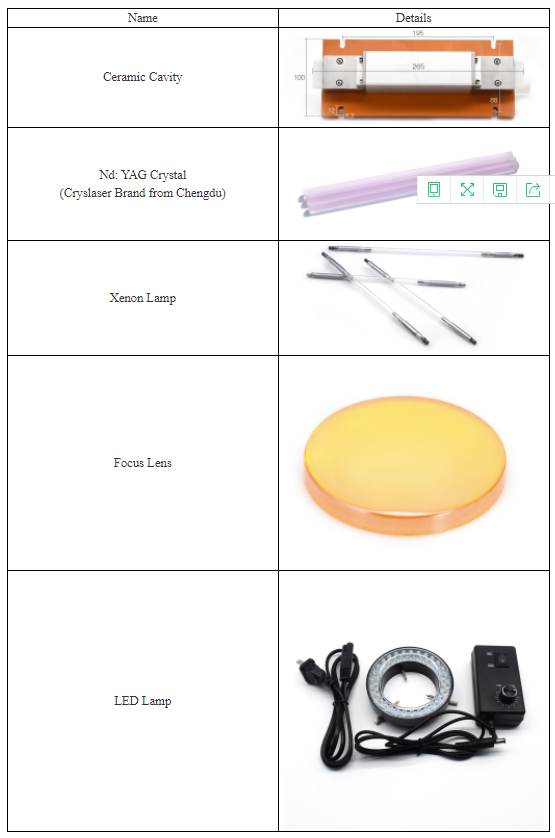

3. Spare parts:

lansenlaser@hotmail.com

lansenlaser@hotmail.com +86 156 6577 8610

+86 156 6577 8610 lansenlaser

lansenlaser sales@lansenlaser.com

sales@lansenlaser.com