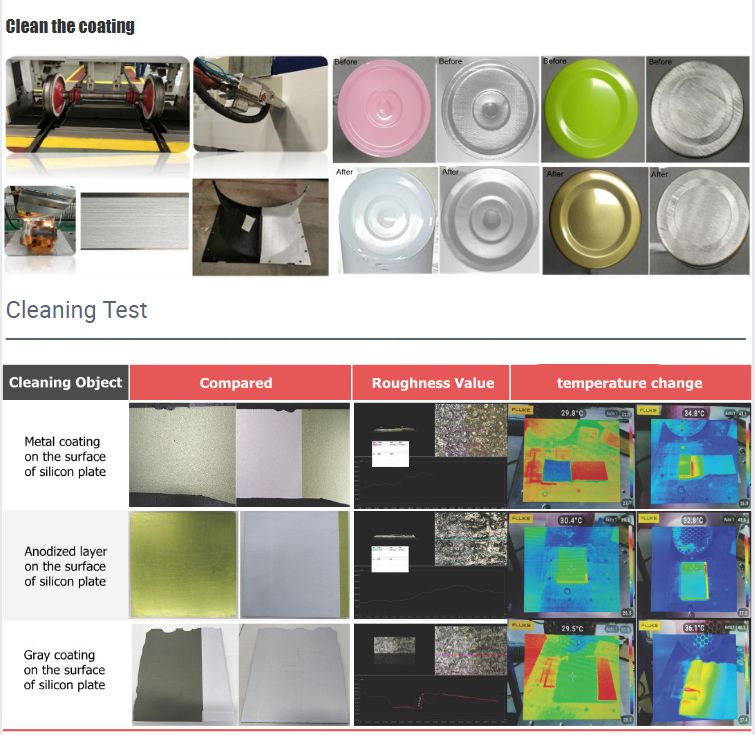

Laser cleaning, on the other hand, is non-contact and non-abrasive, and so will only irradiate the material that you want to get rid of. This makes the process in particular, ideal for cleaning intricate and textured materials. You also have a great deal of control over the beam, meaning you can achieve the desired depth that you want to. Further to this, you can irradiate the whole surface layer of a material, or a much thinner layer, say the topcoat of paint, but not the primer below. Or, should you wish, you can just clean a very small section. If using another process which simply blasts the material, it is hard to enjoy such a high level of control. One of the key benefits in the way that laser cleaning works is that not much waste is left over due to the irradiation process; the substrate is simply vaporised rather than left as waste. The majority of the waste that is left over comes as dust particles and can be easily collected and removed by the user.

It is mostly dust particles that are left behind from the laser cleaning process As if all the above isn’t

enough, the laser cleaning process is also much faster, leaving staff more able to complete other work and

not spend all of their time cleaning!

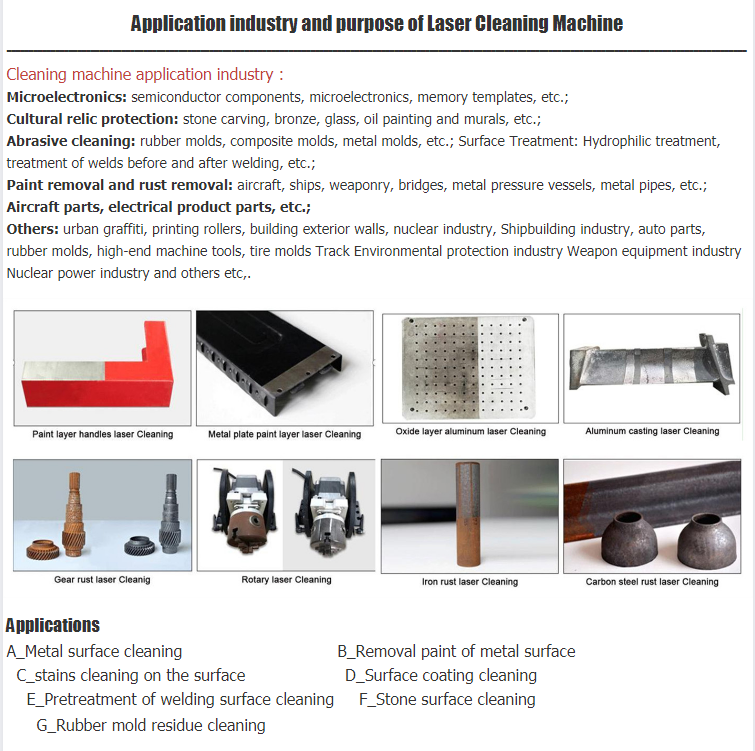

Application industry and purpose of Laser Cleaning Machine

Cleaning machine application industry microelectronics: semiconductor components, microelectronics, memory templates, etc.; cultural relic protection: stone carving, bronze, glass, oil painting and murals, etc.; abrasive cleaning: rubber molds, composite molds, metal molds, etc.; surface Treatment: Hydrophilic treatment, treatment of welds before and after welding, etc.; Paint removal and rust removal: aircraft, ships, weaponry, bridges, metal pressure vessels, metal pipes, etc.; aircraft parts, electrical product parts, etc.; Others: urban graffiti, printing rollers, building exterior walls, nuclear industry, Shipbuilding industry, auto parts, rubber molds, high-end machine tools, tire molds Track Environmental protection industry Weapon equipment industry Nuclear power industry and others etc,.

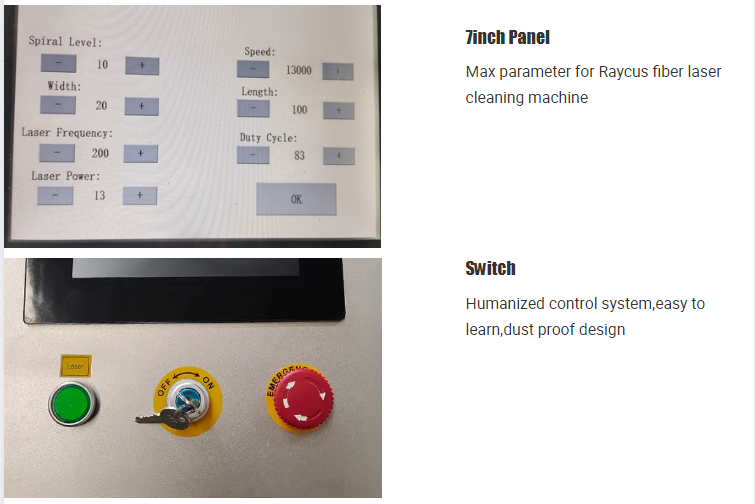

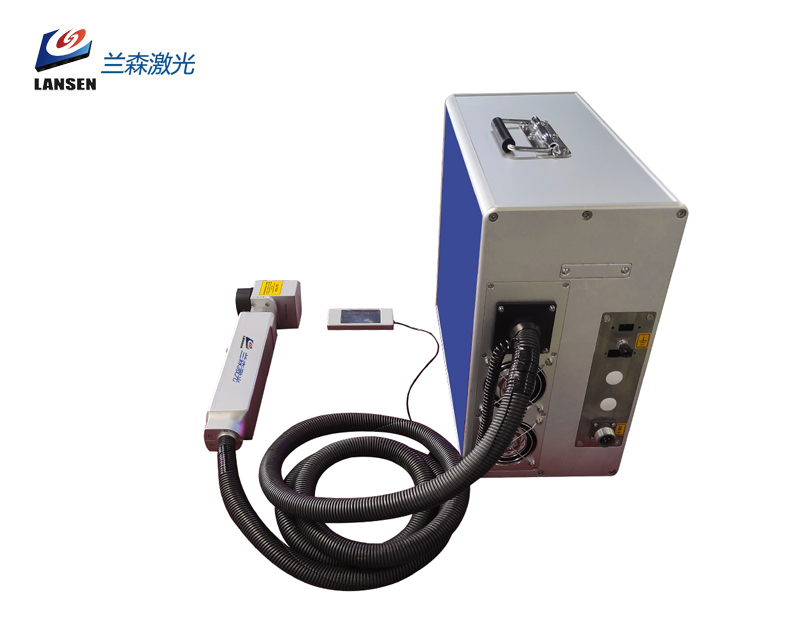

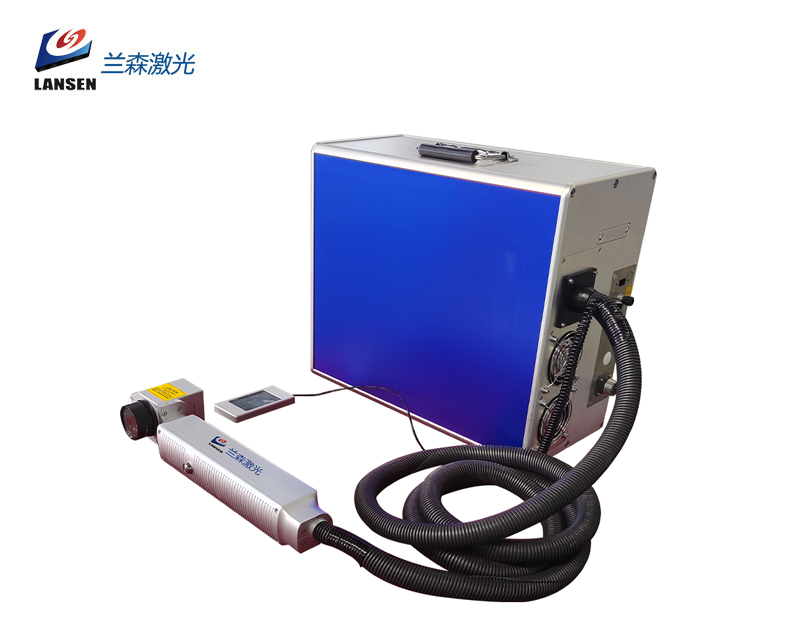

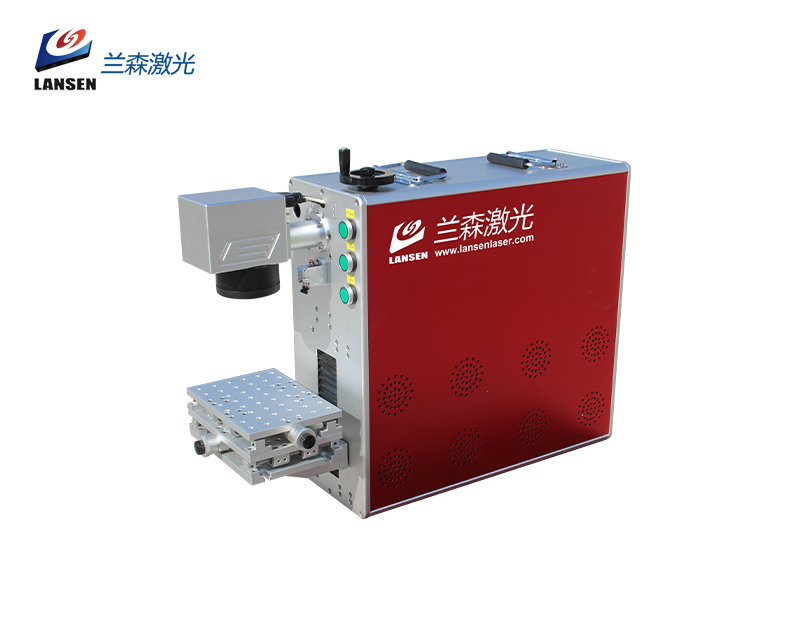

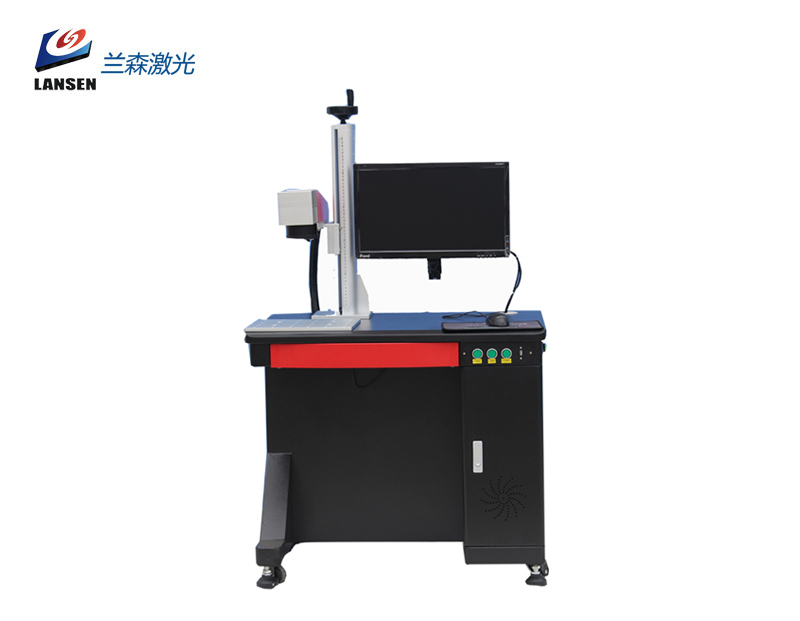

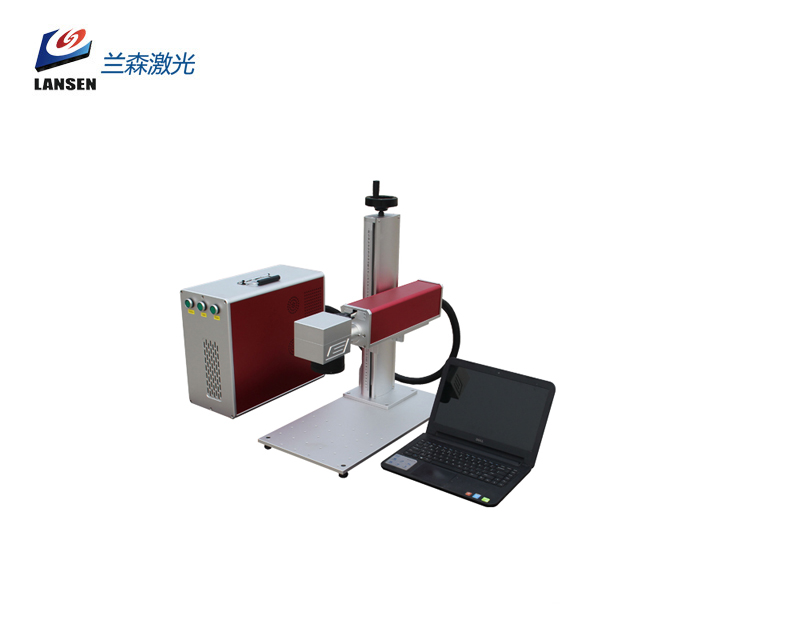

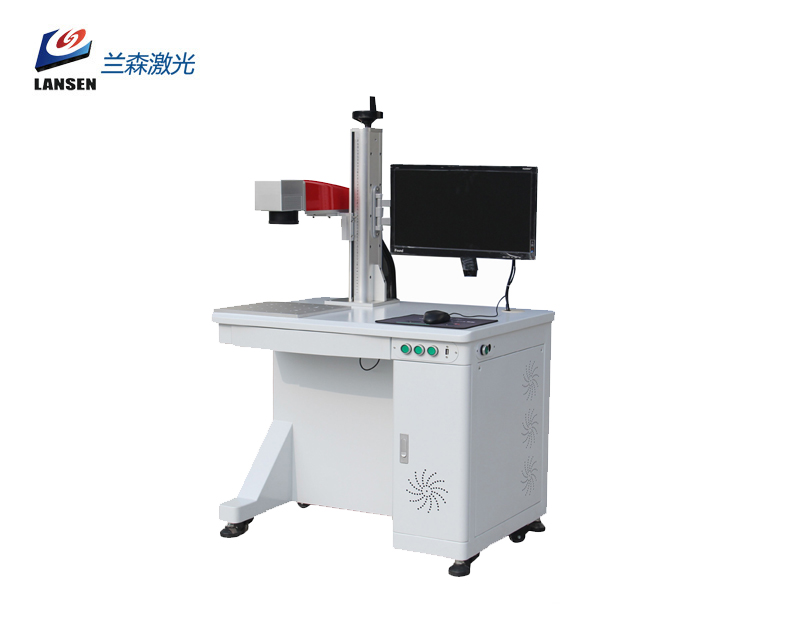

Dynamic Fiber Laser Marking machine Parameters:

Model | LC-P2 |

Laser Power | 50W/ 100W |

Scan head brand | Sino-Galvo |

Cooling way | Air cooling |

Laser Wavelength | 1064nm |

Laser Power | 0-100% |

Laser Frequency | 20-200KHZ |

Clean width | 1-20mm |

Clean length | 1mm、3mm、6mm、12mm、25mm、50mm、100mm |

Clean speed | 1-1000mm/s (adjustable) |

Working temprature | 0- 40 ℃ |

Voltage | 220V±10%, 50-60hz |

LCD control panel size | 3.5inch |

Operation way | Handhold model |

Hand-piece size | 406.5×70×113.7mm |

Hand-piece weight | 2.5±0.1Kg |

Optic cable length (bending radius≥250mm) | 3m, can be customized |

Working Humidity Conditions: | ≤ 80%RH |

Packing size | 630mmX590mmX290mm |

Machine size/Gross weight | 25kg/35.1kg |

Laser cleaning is non-contact and non-abrasive, and so will only irradiate the material that you want to get rid of. This makes the process in particular, ideal for cleaning intricate and textured materials. You also have a great deal of control over the beam, meaning you can achieve the desired depth that you want to. Further to this, you can irradiate the whole surface layer of a material, or a much thinner layer, say the topcoat of paint, but not the primer below. Or, should you wish, you can just clean a very small section. If using another process which simply blasts the material, it is hard to enjoy such a high level of control. One of the key benefits in the way that laser cleaning works is that not much waste is left over due to the irradiation process; the substrate is simply vaporised rather than left as waste. The majority of the waste that is left over comes as dust particles and can be easily collected and removed by the user.

Application industry and purpose of Laser Cleaning Machine

Cleaning machine application industry microelectronics: semiconductor components, microelectronics, memory templates, etc.; cultural relic protection: stone carving, bronze, glass, oil painting and murals, etc.; abrasive cleaning: rubber molds, composite molds, metal molds, etc.; surface Treatment: Hydrophilic treatment, treatment of welds before and after welding, etc.; Paint removal and rust removal: aircraft, ships, weaponry, bridges, metal pressure vessels, metal pipes, etc.; aircraft parts, electrical product parts, etc.; Others: urban graffiti, printing rollers, building exterior walls, nuclear industry, Shipbuilding industry, auto parts, rubber molds, high-end machine tools, tire molds Track Environmental protection industry Weapon equipment industry Nuclear power industry and others etc,.

lansenlaser@hotmail.com

lansenlaser@hotmail.com +86 156 6577 8610

+86 156 6577 8610 lansenlaser

lansenlaser sales@lansenlaser.com

sales@lansenlaser.com